What is Plastic Mold?

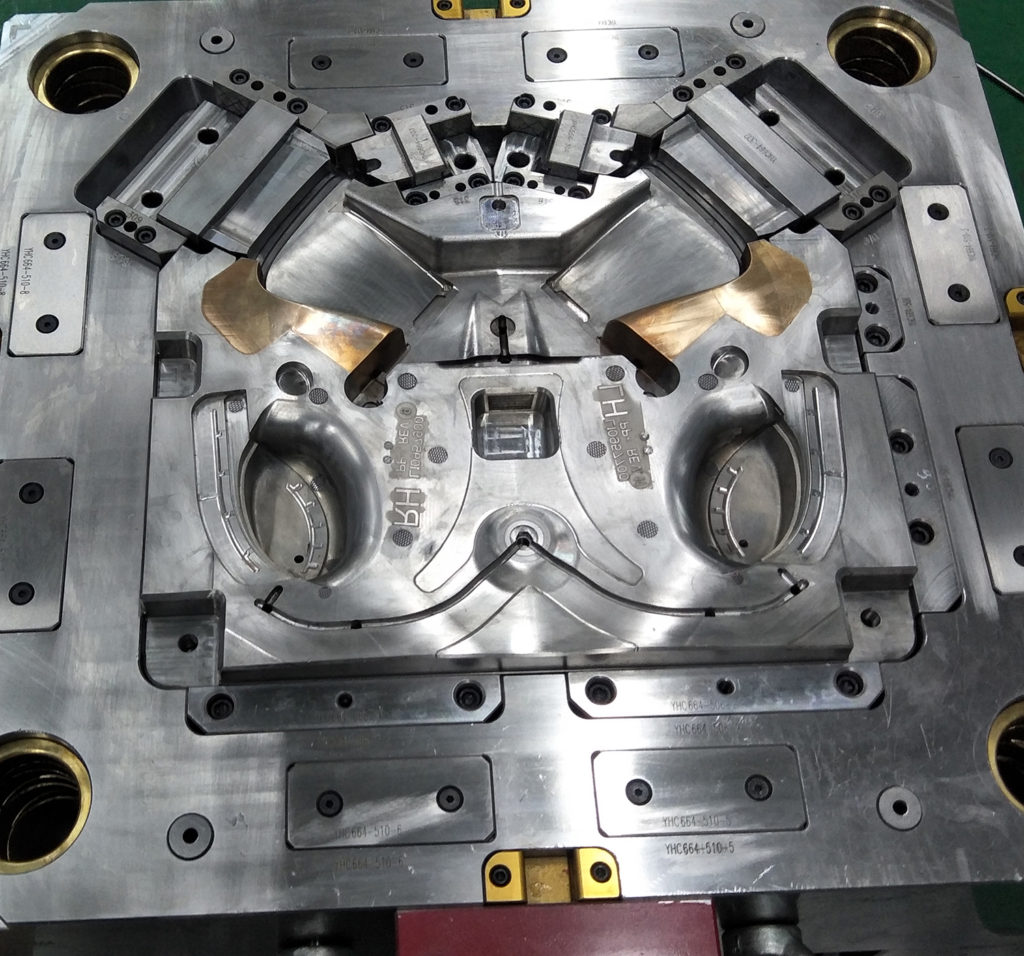

Plastic mold is the abbreviation of a combination mold for compression, extrusion, injection, blow molding and low foam molding. The coordinated changes in mold convex and concave molds and auxiliary molding systems allow for the processing of a range of plastic parts of different shapes and sizes.

Plastic molds are the mother of industry, and new product launches involve plastics.

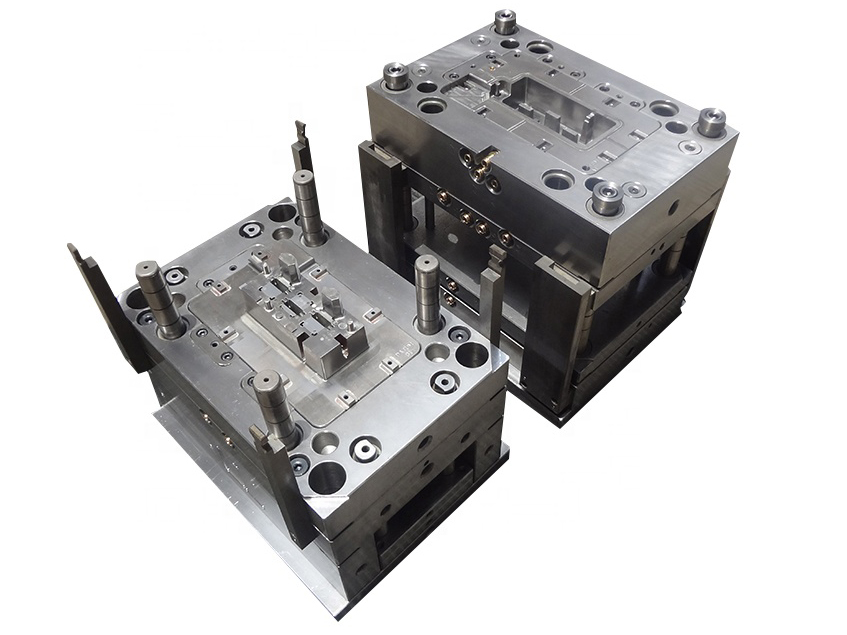

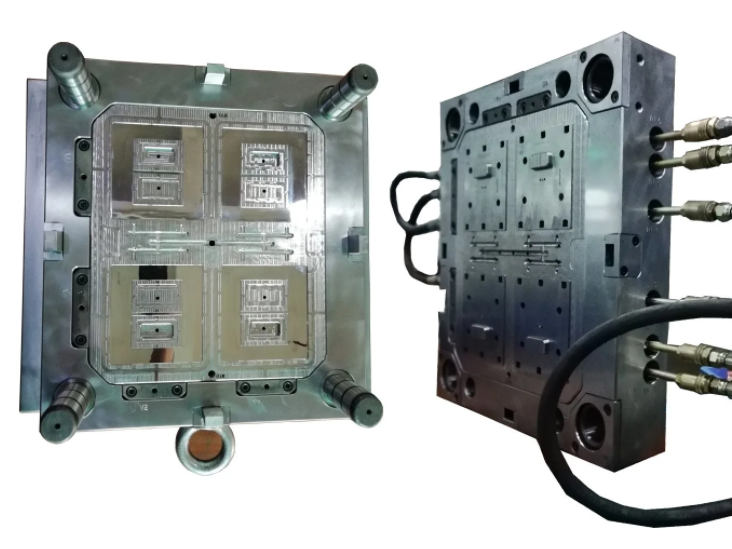

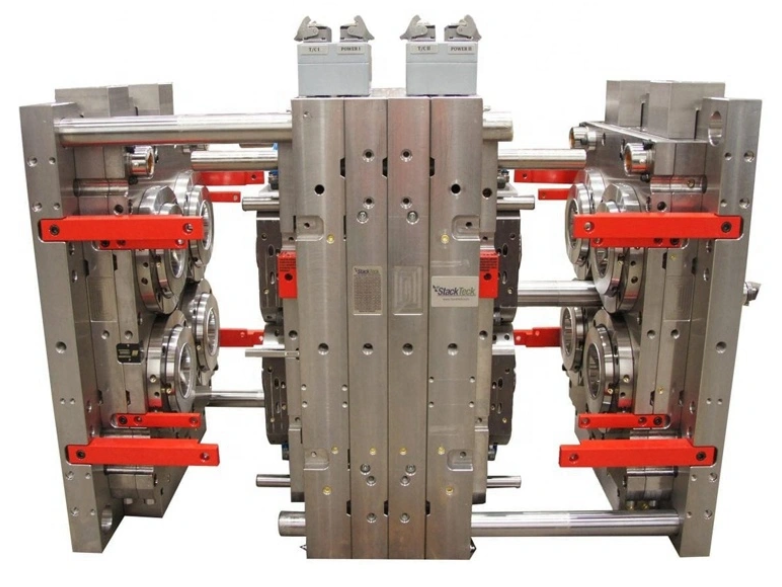

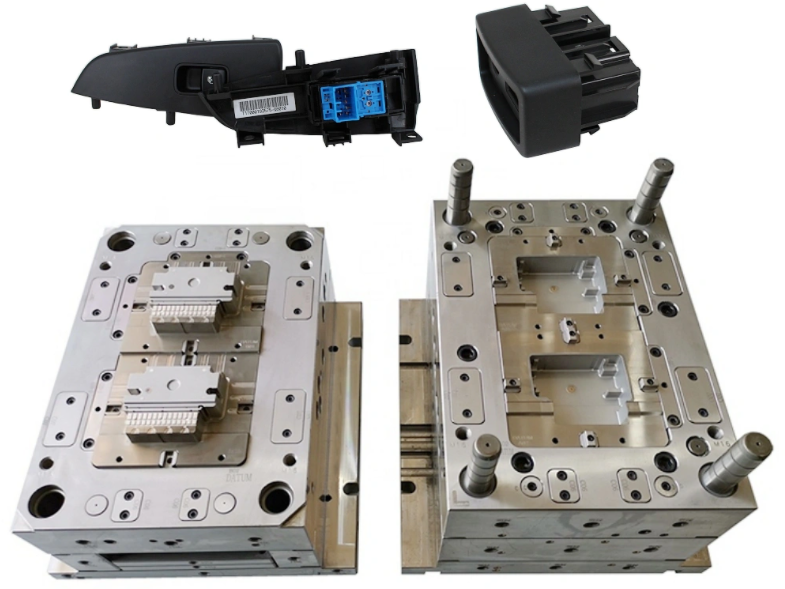

Hongyu's Plastic Mold Services

All-around consideration in quality, cycle time, and service.

- Use high precision CNC machine tools for processing to ensure the quality and performance of the mold.

- Have advanced technology such as hot runner, gas-assisted molding, nitrogen cylinder, etc.

- With CNC, EDM, WEDM machine tools and CNC copy milling equipment, high-precision grinder, high-precision three-coordinate measuring instrument, computer design and related software, etc.

- There are many kinds of moulds, our experienced engineers will choose different types of moulds for forming according to different requirements of parts materials, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, service life, economy, etc.

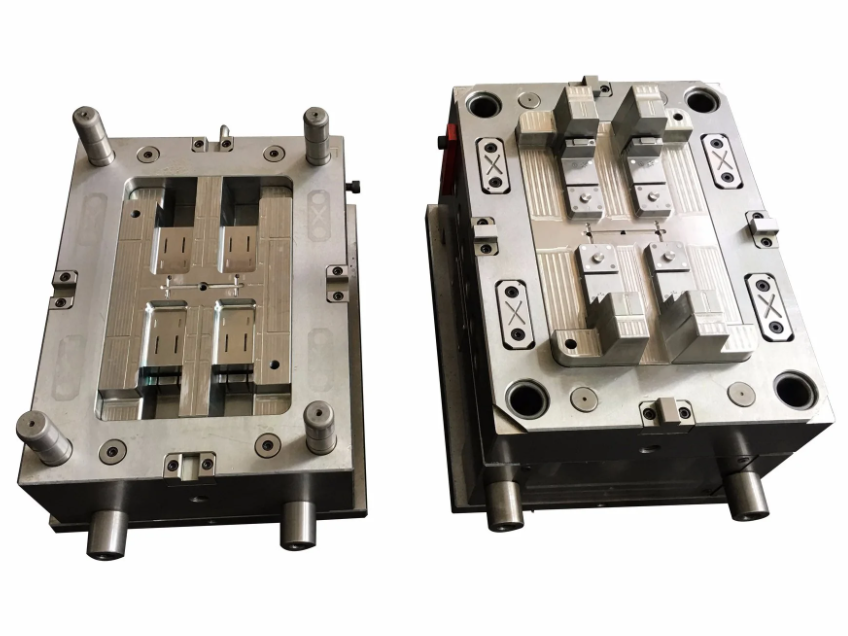

How We Ensure The Quality Of Our Plastic Molds?

5 Processes To Ensure The Quality Of Our Plastic Molds

1. Effective mold product data management, process data management, drawing document management, can ensure the comprehensiveness of the document, the consistency of the drawing version.

2. Through effective, detailed and strict inspection means, we can ensure the consistency and integrity of the mold drawings, processing technology and physical data.

3. Through accurate mold structure design, efficient mold parts processing and accurate parts inspection, it will effectively reduce the cost of the mold and effectively control the quality of the mold.

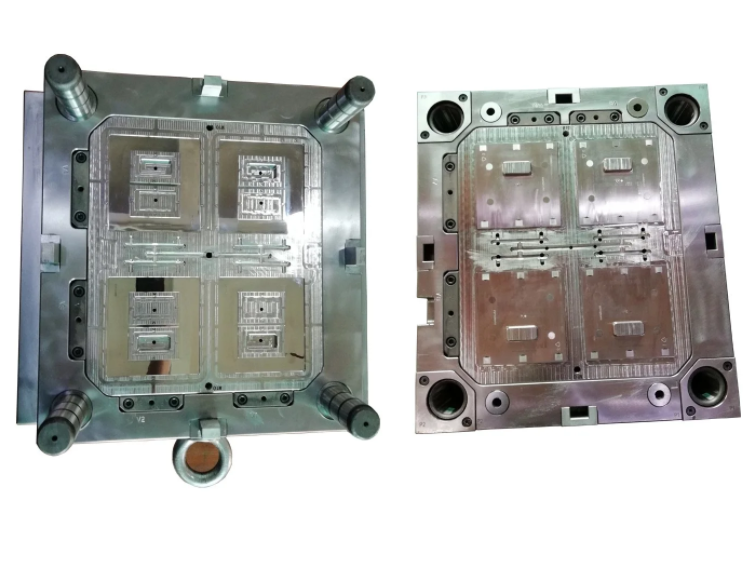

4. Organize and integrate the information of planning, design, processing technology, workshop production situation and human resources together in an organic way to coordinate planning and production to ensure the quality of plastic moulds and deliver on schedule.

5. Have a complete mold production management system, so that mold manufacturing from planning to completion and delivery can achieve all-round tracking management.

Quality is our Life

We own a full set of advanced measuring and testing equipments and staffed with experienced QC engineers, we can promise to our client is that costs the right money to buy the right mold.