What is injection molding?

Injection molding refers to the method of getting molded products by stirring completely molten plastic material by screw at a certain temperature, injecting it into the mold cavity with high pressure, and curing it by cooling.

The advantages of the injection molding method are fast production speed, high efficiency, automatic operation, variety of colors, the shape can be from simple to complex, size can be from large to small, and the product size is accurate, the product is easy to update, can become a complex shape of the parts, injection molding is suitable for mass production and complex shape products and other molding processing fields.

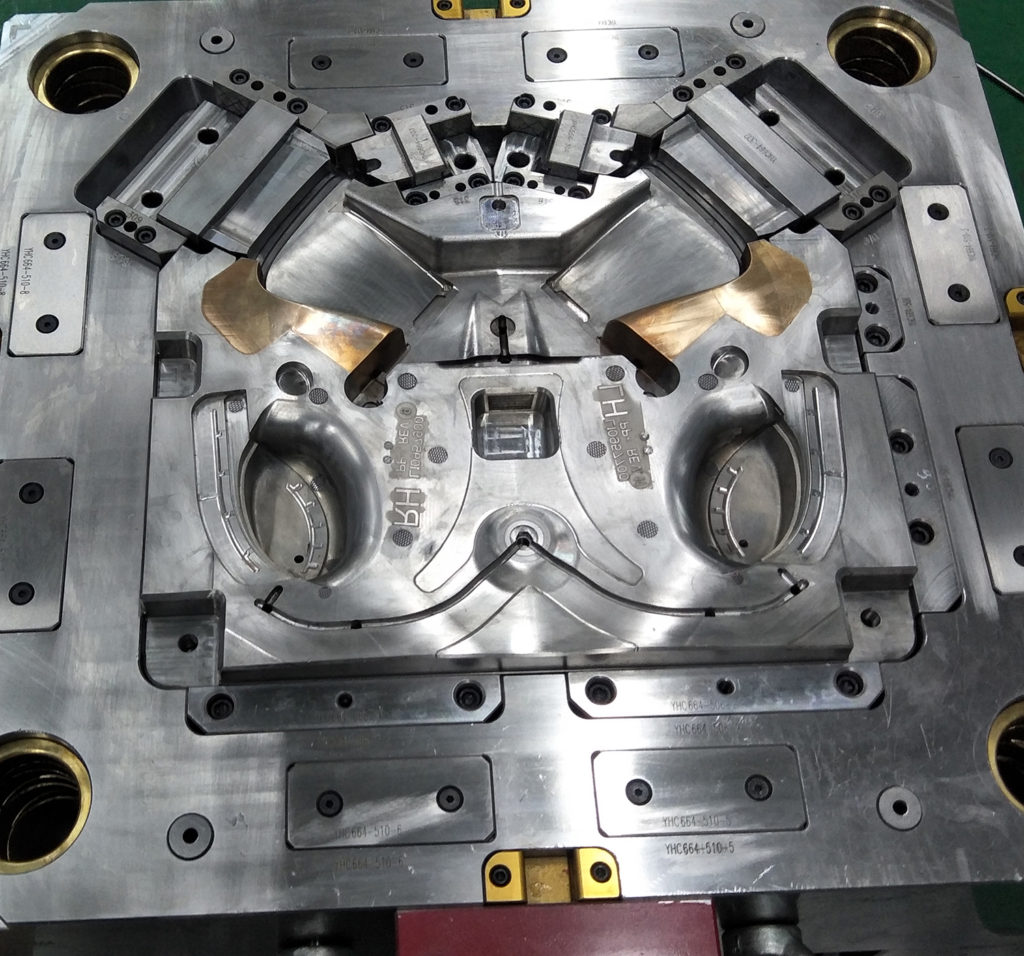

Hongyu's Injection Molding Services

Our services are tailored to your needs

- One Stop Service

- 24-hour quote responses.

- A range of plastic material for choice

- Single-, multi-cavity, and family mold options

- Our engineers have more than 18 years of experience

- Customer-owned the mold

- Quality guaranteed, all parts inspected before shipment

- Injection molding capabilities for the medical device Industry

9 Steps Of The Plastic Injection Molding Process

1. Material enters the barrel

2. Material melts and mixes

3. Volume of material (Shot sizes in the barrel is created)

4. Mold closes

5. Injection of the plastic into the mold cavity

6. Molten material cooled (during this process, steps 1-3 are preparing for the next cycle)

7. Mold opens

8. Part ejects

9. Return to Step 4 for the next cycle

Regular Injection Molding Materials

A broad range of plastic materials are available, if you need other custom plastic material, please let us know.

- ABS

- ABS/PC

- Nylon

- PMMA (Acrylic)

- PP (Polypropylene)

- PE (Polyethylene)

- PEEK

- POM (Acetal/Delrin)

- PVC (Polyvinyl chloride)

- PC (Polycarbonate)

- PS (Polystyrene)

- HDPE (High density polyethylene)

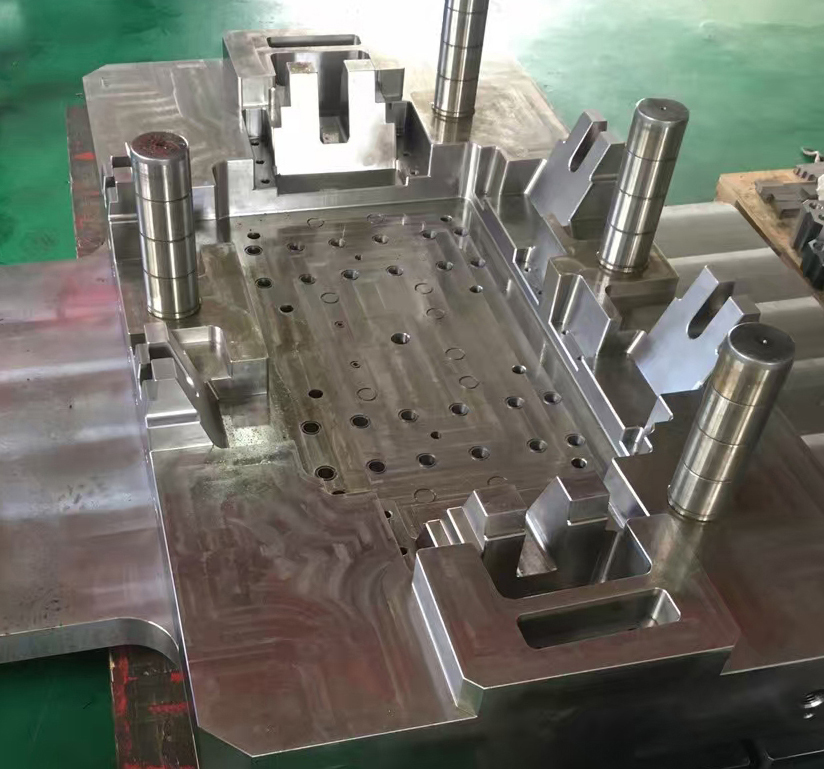

One-Stop Manufacturing

We provide an end-to-end manufacturing solution. We also offer design, toolmaking, packaging, pad printing, assembly, and engineering services. Once your product is complete we can provide warehouse service for your inventory if needed.