CNC Machining Service

- Lead times as fast as 5 business days

- Rapid prototyping and full-scale production

- 100% Full inspection before shipment

- NO MOQ

WHAT IS CNC MACHINING?

CNC is the acronym for Computer Numeric Control, which is a subtractive manufacturing process where the raw material is removed with a variety of precision cutting tools to make a part or product.

The outstanding engineers input layers of data into the machines to establish exact measurements, finishes, and production times.

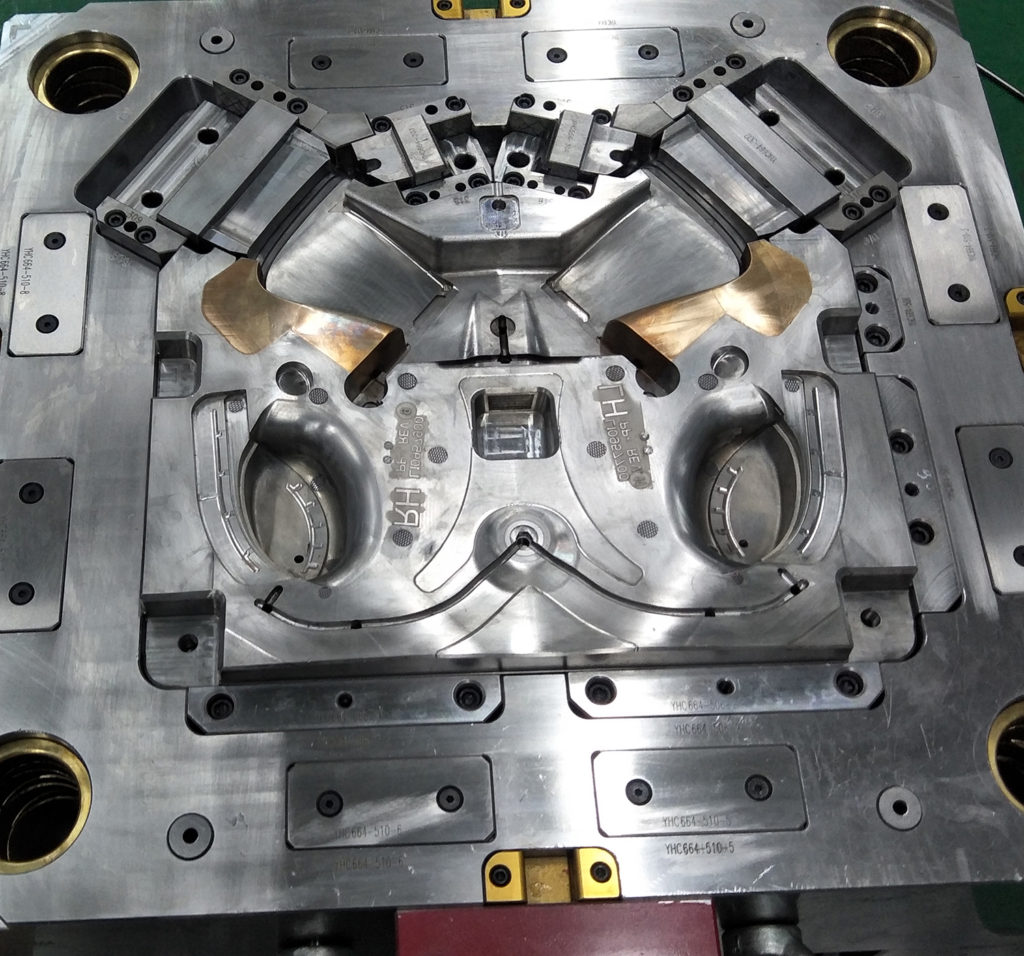

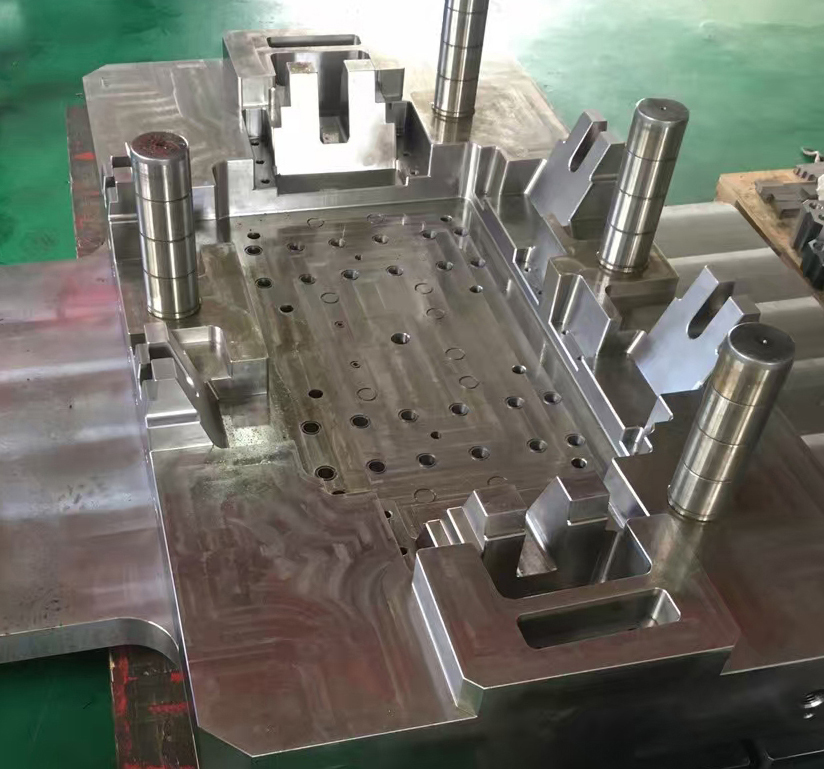

We use CNC machining not only to manufacture parts and prototypes but also to make mold tools, which can be used for our plastic injection molding or pressure die casting services.

CNC Machining Processes

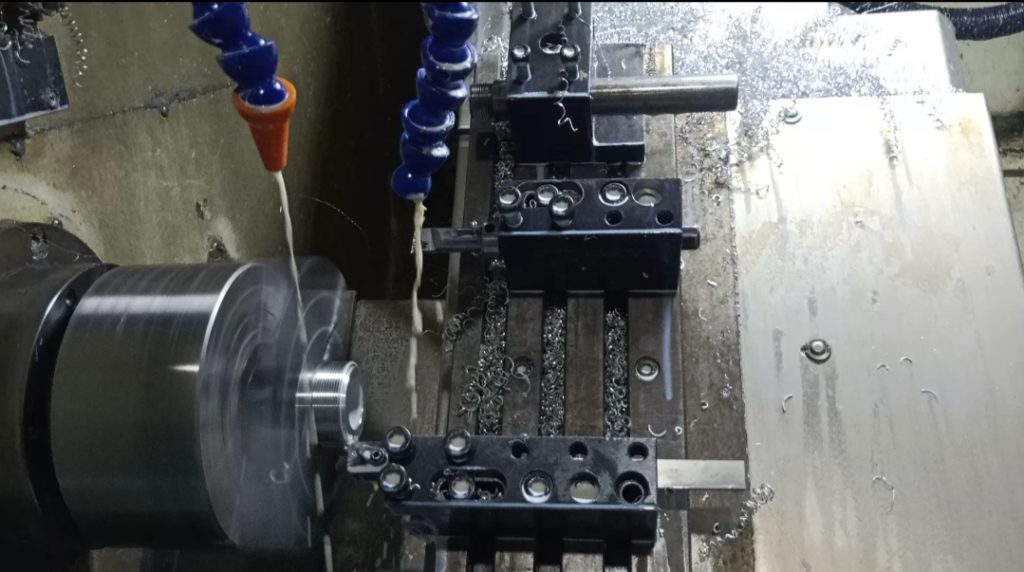

CNC Turning

CNC Turning is a part of lathe machining. Lathe machining mainly uses turning tools to turn the rotating workpiece. The lathe is mainly used for processing shafts, discs, sleeves, and other rotary or non-rotary workpieces with rotary surfaces, and is the most widely used type of machine tool processing in machinery manufacturing and repair factories.

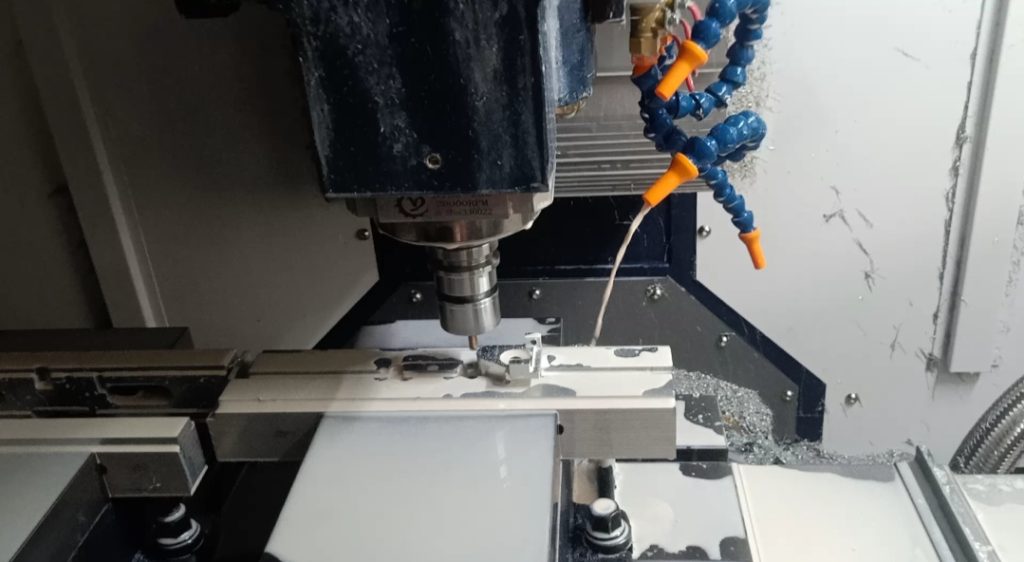

CNC Milling

CNC Milling is to fix the blank and use a high-speed rotating milling cutter to go over the blank and cut out the desired shape and features. CNC milling machines can perform machining of complex shapes and features. Milling and boring machining center can perform 3-axis or multi-axis milling and bore for machining, molds, inspection tools, tire tools, thin-walled complex surfaces, artificial prostheses, blades, etc.

CNC Machining Materials

A broad range of metals and plastics are available

Metal Material

Plastic Material

- Aluminum

- Stainless Steel

- Mild Steel

- Brass

- Copper

- Bronze

- Tool Steel

- Titanium

- Cast Iron

- Zinc Alloy

- Magnesium Alloy

- ABS

- Delrin

- Nylon

- PEEK

- PTFE (Teflon)

- Polycarbonate

- Polyethylene

- PMMA (Acrylic)

- PET

- Polypropylene

- FR4

CNC Surface Finishing Options

A broad range of surface finishes are available

- As machined

- Anodized

- Black Oxide

- Sand blasting

- Powder coated

- Brushed

- Polishing

- Chrome plated

- Laser engraving

- Tin coating

- Phosphating

- Galvanized

- Nickel plating

- Chrome plated

- Carburizing

- Heat treatment

- Electropolishing

- Passivation

Why Choose HY for CNC Machining?

- One Stop Service

- Free PP sample service before mass production

- All parts inspected by QC before shipment

- Quality guaranteed, support return service

- No MOQ, any order quantity is support.