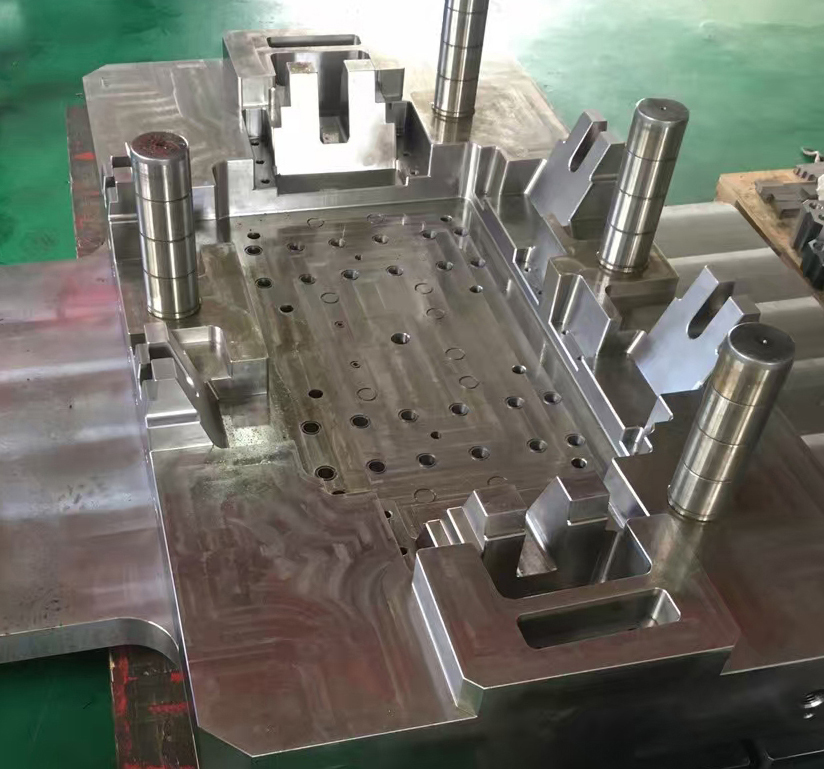

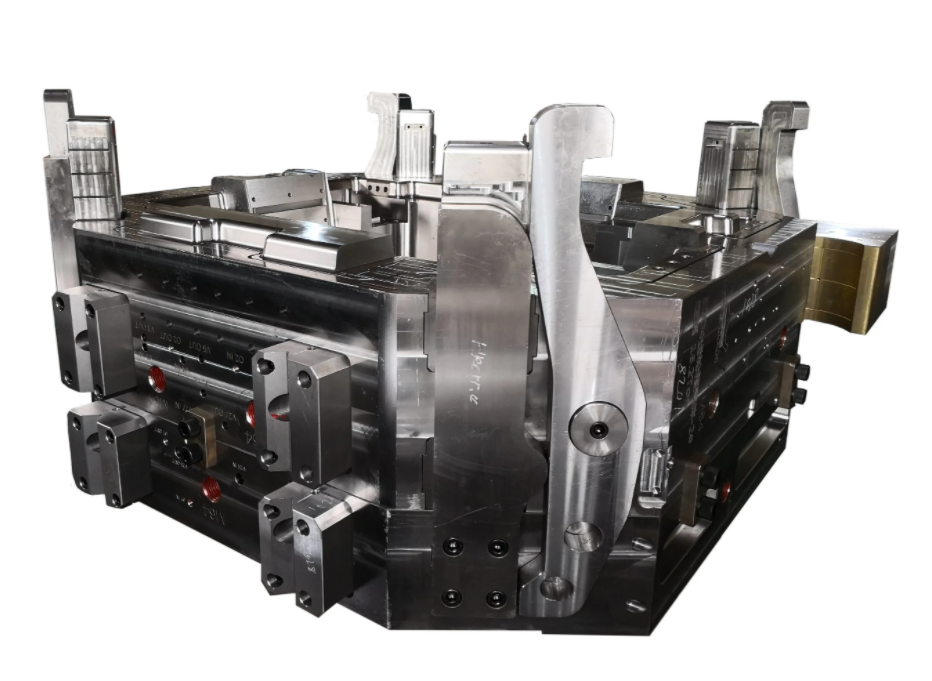

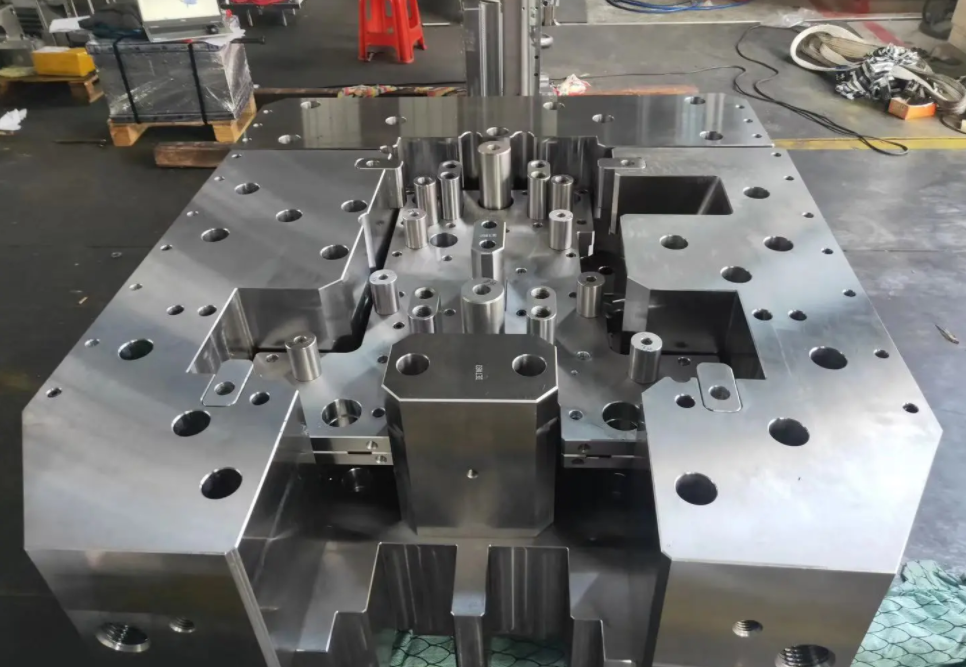

What is Die Casting Mold?

Die casting mold is a tool for casting metal parts, a special die-casting die forging machine to complete the die-casting process tools. The basic process of die casting is: metal liquid first low speed or high speed casting filling into the cavity of the mold, the mold has a movable cavity surface, it is forged with the cooling process of metal liquid pressure, both to eliminate the shrinkage of the blank shrinkage defects, but also to make the internal organization of the blank to the forging state of broken grain. The comprehensive mechanical properties of the blank are significantly improved.

Hongyu's Die Casting Mold Services

All-around consideration in quality, cycle time, and service.

- Use high precision CNC machine tools for processing to ensure the quality and performance of the mold.

- Have advanced technology such as hot runner, gas-assisted molding, nitrogen cylinder, etc.

- With CNC, EDM, WEDM machine tools and CNC copy milling equipment, high-precision grinder, high-precision three-coordinate measuring instrument, computer design and related software, etc.

- There are many kinds of moulds, our experienced engineers will choose different types of moulds for forming according to different requirements of parts materials, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, service life, economy, etc.

Design Steps Of Die-Casting Mold

- 1. Process analysis of die castings. Including alloy, casting structure and die casting technical analysis.

- 2. Process plan design. Including the determination and setting of parting surface, gate position, pouring and overflow system, number of cavities, core-pulling plan and quantity, die-casting ejection plan, and die-casting machine selection.

- 3. Design of pouring and overflow system. Including the determination of process parameters, the calculation of the size of the inner gate, the determination of the shape and size of the gating system, and the calculation of the position and size of the slag ladle of the exhaust groove.

- 4. The design of the general drawing of the die-casting mold.

- 5. Design of die casting mold parts.

Quality is our Life

We own a full set of advanced measuring and testing equipments and staffed with experienced QC engineers, we can promise to our client is that costs the right money to buy the right mold.

Our Other Manufacturing Services

START YOUR DIE CASTING PROJECT TODAY

If it is in the world of die casting, we can handle it with outstanding