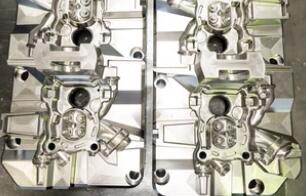

Die-casting mold is a large category of mold. With the rapid development of the automobile and motorcycle industry, the die-casting industry has ushered in a new period of development. At the same time, the comprehensive mechanical properties and service life of die-casting die have been put forward higher requirements.

To meet the ever-increasing demand for performance, it is still difficult to rely on the application of new die materials alone.

All kinds of surface treatment technology must be applied to die-casting die surface treatment in order to meet the requirements of high efficiency, high precision, and high life of the die-casting die.

In all kinds of molds, die-casting mold working conditions are more demanding.

Die casting is to make molten metal in the high-pressure, high-speed filling mold cavity and die-casting molding, in the process of repeated contact with hot metal.

Therefore, the die-casting die is required to have high thermal fatigue resistance, thermal conductivity wears resistance, corrosion resistance, impact toughness, red hardness, good demoulding and so on. Therefore, the die-casting die surface treatment technology requirements are higher. In recent years, a variety of die-casting die surface treatments of new technologies continues to emerge.

In general, there are three broad categories:

1. Improved techniques for traditional heat treatment processes.

2. Surface modification technology, including surface thermal diffusion treatment, surface transformation strengthening, electric spark strengthening technology and so on.

3. Coating technology, including electroless plating.

Improved technique for traditional heat treatment processes

The traditional heat treatment process of aluminum alloy die-casting die is quenching-tempering. Later, surface treatment technology was developed.

Due to the variety of die-casting die materials, the same surface treatment technology and process applied to different materials will produce different results.

On the basis of traditional technology, the suitable processing technology is put forward for different die materials, so as to improve die performance and prolong die life. Another development direction of heat treatment technology improvement is to combine traditional heat treatment technology with advanced surface treatment technology to improve the service life of die casting die.

For example, the method of chemical heat treatment, carbonitriding, combined with conventional quenching and tempering process of N Q N (namely carbonitriding-quenching-carbonitriding) composite strengthening, not only get higher surface hardness, furthermore, the effective hardening depth increases, the hardness gradient distribution of the infiltrated layer is reasonable, and the tempering stability and corrosion resistance are improved.

As a result, the surface quality and performance of the die-casting die are improved greatly while the die-casting die has good core performance.

Surface modification technology

1) Surface thermal diffusion technique

This type includes carburizing, nitriding, boronizing and carbonitriding, sulfur carbonitriding, and so on.

2) Carburizing and carbonitriding

The carburizing process is used in cold, hot working, and surface strengthening of plastic moulds. Can increase the life of the mold.

For example, the die-casting die made of 3cr2w8v steel was carburized, then quenched at 1140ー1150 °C and tempered twice at 550 °c. the surface hardness of the die-casting die could reach HRC 56ー61. The service life of the die casting Non-ferrous metal and its alloy is increased 1. 8 ~ 3.0 times.

During carburizing, the main processes are solid powder carburizing, gas carburizing, vacuum carburizing, ion carburizing, and carbonitriding by adding nitrogen in carburizing atmosphere. Among them, vacuum carburizing and ion carburizing are technologies developed in recent 20 years. The technique is characterized by rapid infiltration, uniform infiltration layer, gentle carbon concentration gradient and small deformation of workpiece. In the mold surface especially the precision mold surface processing plays an increasingly important role.

3) Nitriding and related low temperature thermal diffusion technology

This type includes nitriding, ion nitriding, carbonitriding, oxygen-nitrogen nitriding, sulfur nitrogen nitriding, and sulfur carbon-nitrogen, oxygen-nitrogen sulfur three-way nitriding, and so on. These methods are simple, adaptable, low diffusion temperature (480 ~ 600 °C), and little deformation. Especially suitable for precision mold surface strengthening. Moreover, the nitriding layer has high hardness, good wear resistance, and good anti-adhesion die performance. The service life of 3CR2W8V steel die-casting die after nitriding at 520ー540 °C is 2ー3 times longer than that of the die-casting die without nitriding.

Many die-casting dies made of H 13 steel in the United States are nitrided. The surface hardness of HRC 65 ~ 70 was obtained by nitriding instead of one tempering. But the hardness of the die core is low and the toughness is good, so excellent comprehensive mechanical properties are obtained.

Nitriding is a common surface treatment process for die-casting dies. However, when the nitrided layer appears a thin and brittle white layer, it can not resist the effect of alternating thermal stress, so it is easy to produce micro-cracks and reduce the thermal fatigue resistance. Therefore, in the nitriding process, it is necessary to strictly control the process to avoid the occurrence of the brittle layer.

Recently, secondary and multiple nitriding processes have been proposed abroad. The nitriding layer can be decomposed by repeated nitriding, and the thickness of the nitriding layer can be increased. At the same time, there is a very thick residual stress layer on the surface of the die, so that the service life of the die can be significantly increased. In addition, the method of Salt Bath carbonitriding and Salt Bath S-N-C carbonitriding is also adopted. These processes are widely used in foreign countries. Such as T F I + a b I process, is in the salt bath nitrocarburizing and then alkaline oxidation in the salt bath immersion. The surface of the workpiece is oxidized and black, and its wear resistance, corrosion resistance, and heat resistance are improved. The service life of the die-casting die of aluminum alloy treated by this method is increased by hundreds of hours. The French developed Oxy nitriding process, which is then nitrided, is even more characteristic when applied to Non-ferrous metal die-casting molds.

4) Boronizing

Due to the high hardness (f e b: H V 1800 ~ 2300, F E 2B: H V 1300 ~ 1500), wear-resistance and red hardness of the boriding layer, as well as certain corrosion resistance and adhesion resistance, the boriding technology has obtained better application effect in die and mould industry.

However, due to the harsh working conditions of the die-casting die, boriding technology is seldom applied to the surface treatment of the die-casting die. However, in recent years, an improved boronizing method has been developed to solve the above problems. And can be applied to die-casting die surface treatment, such as multi-element, powder coating infiltration, etc. .

The method of powder boronizing is to mix boron compounds with other boronizing agents and then coat the surface of the die casting mould.

After the liquid volatilized, it was packed and sealed according to the general method of powder boronizing, heated at 920 °C and kept warm for 8 hours, then air-cooled. The hardness, wear resistance, and bending strength of the surface layer of the die are improved, and the service life of the die is increased more than 2 times.

5) Rare earth surface strengthening

In recent years, the method of adding rare earth elements to die surface strengthening has been widely recommended.

This is because rare earth elements have many functions, such as increasing the permeation rate, strengthening the surface, and purifying the surface. It has a great effect on improving the surface structure, surface physical, chemical and mechanical properties of the die. It can increase the permeation rate, strengthen the surface and form rare-earth compounds.

At the same time, the harmful effect of trace impurity on the grain boundary can be eliminated and the grain boundary on the surface of the die cavity can be strengthened and stabilized.

In addition, rare earth elements react with harmful elements in steel to form compounds with high melting points, which can restrain the segregation of these harmful elements on grain boundary and reduce the brittleness of the deep layer.

The addition of rare earth elements to the surface strengthening treatment of die-casting dies can obviously increase the thickness and surface hardness of the infiltrated layers.

At the same time, the microstructure of the diffusion layer is fine and the hardness gradient is decreased, so that the wear resistance, cold resistance, and thermal fatigue of the die are improved remarkably, and the die life is greatly increased.

At present, the methods used in die casting die cavity surface treatment are rare earth carbonitriding, rare earth carbonitriding, rare earth boron aluminizing, rare earth soft nitriding, rare earth sulfur nitrogen carbonitriding, and so on.

6) Laser surface treatment

Laser surface treatment is the use of laser beam heating so that the surface of the workpiece quickly melts a certain depth of the thin layer.

At the same time, the alloy elements are coated on the surface of the workpiece by means of vacuum evaporation, electroplating, and ion implantation, and are fully fused with the base metal under laser irradiation, after condensation, a special alloy layer with a thickness of 10 ~ 1000μ M was obtained on the surface of the die, and the cooling rate was equivalent to that of quenching.

If the surface of H 13 steel is treated by laser rapid melting process, the melt zone has high hardness, good thermal stability, and high resistance to plastic deformation, which can obviously restrain the initiation and propagation of fatigue crack.

Recently, the laser cladding of the V C layer on the H 13 substrate was carried out by Sacha and Dahotoro, and the results show that the obtained die surface is continuous, compact, and non-porous V C Steel composite coating. It not only has a strong oxidation resistance at 600 °C but also has a strong resistance to molten metal reduction. With the development of surface modification technology, the electro-spark deposition (EDM) technology of Cermet has been developed.

Under the action of the electric field, the process produces instantaneous high temperature and high-pressure zone on the surface of base metal. At the same time, the ionized cermet material is infiltrated to form a metallurgical bond on the surface.

At the same time, instantaneous phase transformation occurs on the surface of the base metal, forming martensite and fine austenite structure.

This process is different from welding, spray plating, or element infiltration should be between the two in a process. It makes good use of the properties of high wear resistance, high-temperature resistance, and corrosion resistance of cermet materials. Moreover, the process is simple and the cost is low. It is a new way of die-casting die surface treatment.

3 Coating technology

As a kind of mold strengthening technology, coating technology is mainly used in plastic molds, glass molds, rubber molds, stamping molds, and other mold surface treatments with relatively simple working environments.

Die-casting molds need to withstand the harsh environment of alternating hot and cold stress, so coating technology is generally not used to strengthen the surface of die-casting molds.

However, in recent years, it has been reported that the surface of the die-casting mold has been strengthened by the method of chemical composite plating to improve the adhesion resistance and demoldability of the mold surface.

In this method, (Ni P)-PTFE composite plating is carried out after infiltrating polytetrafluoroethylene particles on an aluminum-based die-casting mold. Experiments have proved that this method is feasible in process and performance, and greatly reduces the friction coefficient of the mold surface.

Concluding remarks

Mold pressure processing is an important part of mechanical manufacturing. The level, quality, and life of molds are closely related to the surface strengthening technology of aluminum alloy die-casting molds. With the advancement of science and technology, various mold surface treatment technologies have made great progress in recent years.

Shown in:

①The improvement of the traditional heat treatment process and its combination with other new processes.

②Surface modification technology, including carburizing, low-temperature thermal diffusion (various nitriding, carbonitriding, ion nitriding, ternary co-infiltration, etc.), salt bath thermal diffusion, boronizing, rare earth surface strengthening, laser Surface treatment and EDM deposition of cermet, etc.

③Coating technology and other aspects.

Do you have any supplements and questions about this? You can comment below and we will exchange and explore together.

2人评论了“All You Need To Know About The Technology Of Die-casting Mold Surface Finish”

Great content! Keep up the good work!

Thanks!