Today, I will talk to all of you about the various knowledge of “aluminum and aluminum alloy” numbering. Hope to help everyone.

The specific gravity of aluminum is lighter, the spring back during forming is small, and the strength is relatively high, which is close to or exceeds that of high-quality steel. Good plasticity, when the product is more complicated, it is easier to control than stainless steel, and it has excellent electrical conductivity, thermal conductivity, and corrosion resistance. In addition, the current surface treatment processes for aluminum materials such as anodizing, wire drawing, and sandblasting have been very mature. The use of aluminum in mobile phones is also very much

According to the processing method of aluminum alloy, it can be divided into deformed aluminum alloy and cast aluminum alloy. The numbers of aluminum and aluminum alloys are mainly divided into eight series.

Alloy Grades

International grades (with four Arabic numerals, now commonly used):

1XXX indicates the pure aluminum series of 99% or more, such as 1050, 1100

2XXX indicates aluminum-copper alloy series, such as 2014

3XXX means aluminum-manganese alloy series, such as 3003

4XXX means aluminum-silicon alloy series, such as 4032

5XXX means aluminum-magnesium alloy series, such as 5052

6XXX means aluminum-magnesium-silicon alloy series, such as 6061, 6063

7XXX means aluminum-zinc alloy series such as 7001

8XXX means alloy system other than above

1000 Series

Among all series, 1000 series belongs to a series with the most aluminum content, and the purity can reach 99.00% or more. 1000 series aluminum sheet is determined according to the last two Arabic numerals to determine the minimum aluminum content of this series. For example, the last two Arabic numerals of 1050 series are 50, according to the international grade naming principle, the aluminum content must reach 99.5% or more to be qualified products.

The aluminum of 1000 series has good formability and surface treatment, and its corrosion resistance is the best among aluminum alloys. Its strength is low, and the higher the purity, the lower the strength.

The common ones used in cell phones are 1050, 1070, 1080, 1085 and 1100, which are made by simple extrusion molding (without bending). Among them, 1050 and 1100 can do chemical sanding, glossy, matte, normal effect. There are more obvious material grain, coloring effect is good. 1080 and 1085 mirror aluminum is often used to do bright letters, matte effect, no obvious material grain.

1000 series of aluminum are relatively soft, mainly used to do decorative parts or interior parts.

2000 Series

It is characterized by high hardness, but poor corrosion resistance, with the highest content of copper. 2000 series aluminum alloy represents 2024, 2A16, 2A02. The copper content of 2000 series aluminum plate is about 3-5%.

The 2000 series aluminum rods belong to aviation aluminum materials and are used as structural materials. It is not often used in conventional industries at present.

3000 Series

3000 series aluminum rods are made of manganese as the main component. 3000 series aluminum alloys mainly represent 3003, 3105, and 3A21. The content is between 1.0-1.5, which is a series with better anti-rust function.

Commonly used as tanks and tanks for liquid products, construction processing parts, construction tools, various lighting components, and various pressure vessels and pipes for sheet processing. The formability, solubility and corrosion resistance are good.

4000 Series

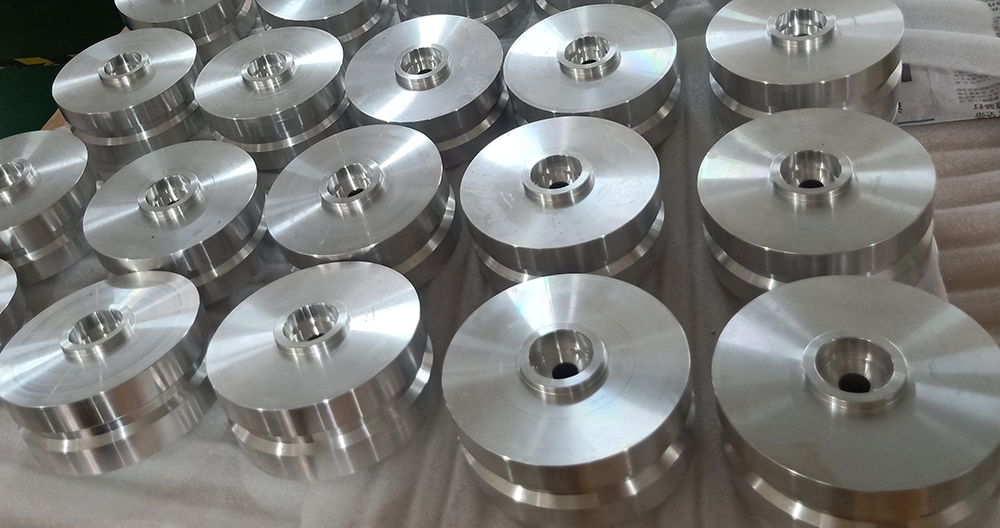

The 4000 series usually have a silicon content between 4.5-6.0%. The higher the silicon content, the higher the strength. The 4000 series aluminum rods are represented by 4A01, and the 4000 series aluminum plates belong to the series with higher silicon content. It has good soup flow and little solidification shrinkage. It belongs to construction materials, mechanical parts, forging materials, and welding materials. Low melting point, good corrosion resistance, heat resistance and wear resistance.

5000 Series

The 5000 series aluminum rods belong to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. The 5000 series aluminum alloy represents the 5052, 5005, 5083, and 5A05 series. It can also be called aluminum-magnesium alloy. The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series. It is also widely used in conventional industries.

The most commonly used mobile phone is 5052. It is the most representative alloy with medium strength. Good corrosion resistance, weldability and formability, especially high fatigue strength and good seawater resistance. It is often used to make products with high strength requirements. But its coloring effect is not ideal, so it is suitable for sandblasting process. Not suitable for chemical sanding, matting, etc. The molding method is mainly used for casting molding, which is not suitable for extrusion molding.

6000 Series Aluminum Alloy

6000 series aluminum alloy represents 6061, which mainly contains two elements: magnesium and silicon. Concentrate the advantages of 4000 series and 5000 series. 6061 is a cold-treated aluminum forged product, suitable for applications with high requirements for corrosion resistance and oxidation. Good workability, easy coating and good processability.

6061 and 6063 are more commonly used on mobile phones. Among them, the strength of 6061 is higher than that of 6063. Using casting molding, it can cast more complicated structures and can be used as parts with buckles, such as battery covers.

7000 Series

The 7000 series mainly contains zinc. 7000 series aluminum alloy represents 7075. It also belongs to the aviation series, which is an aluminum-magnesium-zinc-copper alloy. It is a heat-treatable alloy and belongs to super hard aluminum alloy with good wear resistance.

8000 Series

The more commonly used 8000 series aluminum alloy is 8011, which belongs to other series. Most applications are aluminum foil. It is not commonly used in the production of aluminum rods.