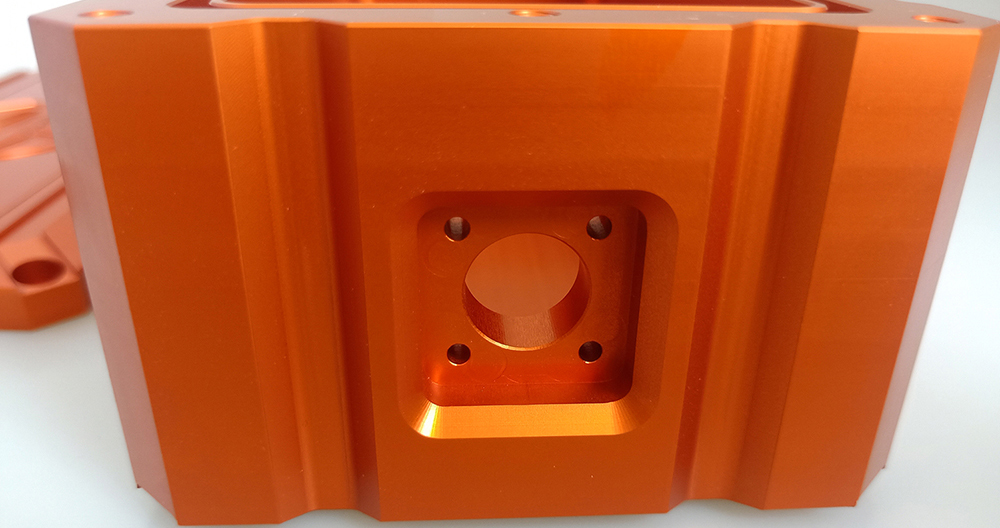

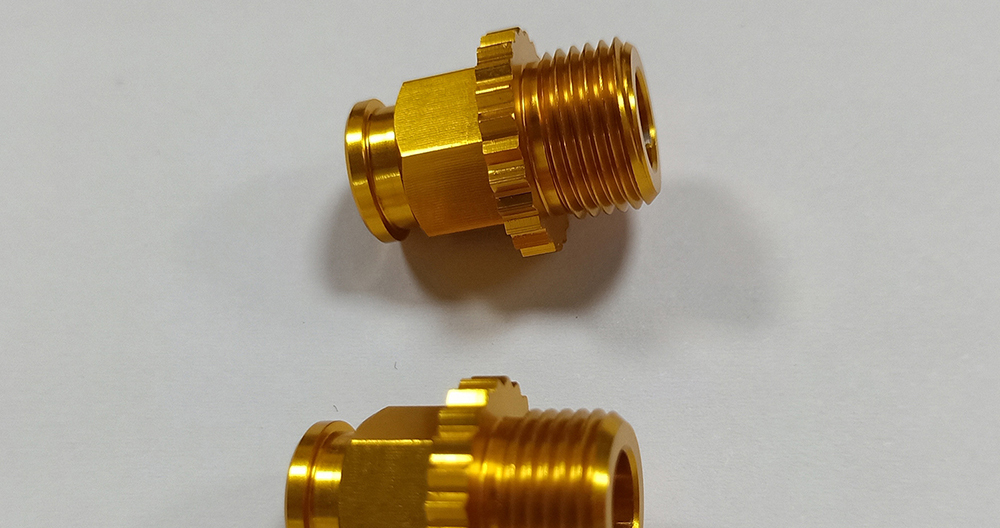

With the development of aluminum processing, the anodizing process, a representative of aluminum surface treatment, is increasingly used in many machined aluminum parts. The thickness of the oxide film obtained by anodic oxidation of aluminum alloy products is generally 5-20um. And the thickness of hard anodic oxide film can reach 30-150um. Let’s see together what are the benefits of anodizing.

1. Higher corrosion resistance

It is generally believed that sweat is very corrosive, and many metals are easily corroded by sweat. The anodic oxide film has strong corrosion resistance because it is an oxide and does not conduct electricity. Even if it is exposed to sweat, it will corrode very slowly.

After testing, the anodic oxide film of pure aluminum has better corrosion resistance than that of aluminum alloy. This is due to the inclusion of alloy components or the formation of metal compounds that cannot be oxidized or dissolved, resulting in discontinuity or voids in the oxide film, which greatly reduces the corrosion resistance of the oxide film. Therefore, the film obtained after anodic oxidation can improve its corrosion resistance.

2. Higher hardness

The hardness of the anodic oxide film is much higher than that of the aluminum substrate: the hardness of the substrate is about HV100, the hardness of the ordinary anodic oxide film is about HV300, while the hard anodic oxide film can reach about HV500.

The hardness of anodic oxide film is not only high but also has good wear resistance. Especially the surface layer of porous oxide film has the ability to adsorb lubricant, which can further improve the wear resistance of the surface.

3. Stronger adsorption ability with anodizing

The anodic oxide film of aluminum and aluminum alloy is porous structure, which has strong adsorption ability. Therefore, filling the holes with various pigments, lubricants and resins can further improve the protection, insulation, wear resistance and decorative properties of aluminum products.

4. Very good insulation performance with anodizing

The anodic oxide film of aluminum and aluminum alloy does not have the conductive properties of metal, but becomes a good insulating material.

5. Excellent adiabatic and thermal resistance performance

This is because the thermal conductivity of anodic oxide film is much lower than that of pure aluminum: anodic oxide film can withstand temperature of about 1500℃, while pure aluminum can only withstand 660℃.